Celectis develops subcomponents, balance of plants, energy systems and offers general engineering solutions and testing facilities for fuel cells, electrolysers and chemical converters

Solid Oxide Fuel Cell, Electrolysis, and new energy solutions are moving fast. Our mission is to provide clean energy and novel engineering solutions to enable an emission-free society. Celectis is built upon experience gained over more than 40 years in sciences and engineering which includes:

- High and low temperature fuel cells

- High and low temperature electrolysis

- Chemical converters such as methanation reactor, ammonia cracker, etc.

- Process engineering

- Mechanical design and simulation

- Power electronics and process automation

CLEAN ENERGY

We are deeply committed to advance clean energy technologies and promote a sustainable future. Our innovative solutions are designed to reduce carbon footprint, improve energy efficiency and increase components lifetime

Green Hydrogen

Celectis is specialized in the production of green hydrogen, offering environmentally-friendly alternatives to today's energy sources. We harness renewable energies to produce hydrogen, guaranteeing a cleaner energy cycle with superior performance

Engineering

Our engineering services and unique laboratory support the development and the implementation of cutting-edge technologies in the clean energy sector. We offer customized solutions and state-of-the-art infrastructure meeting the latest security standards to meet our customers' needs and ensuring proximity, performance, security and reliability

Products

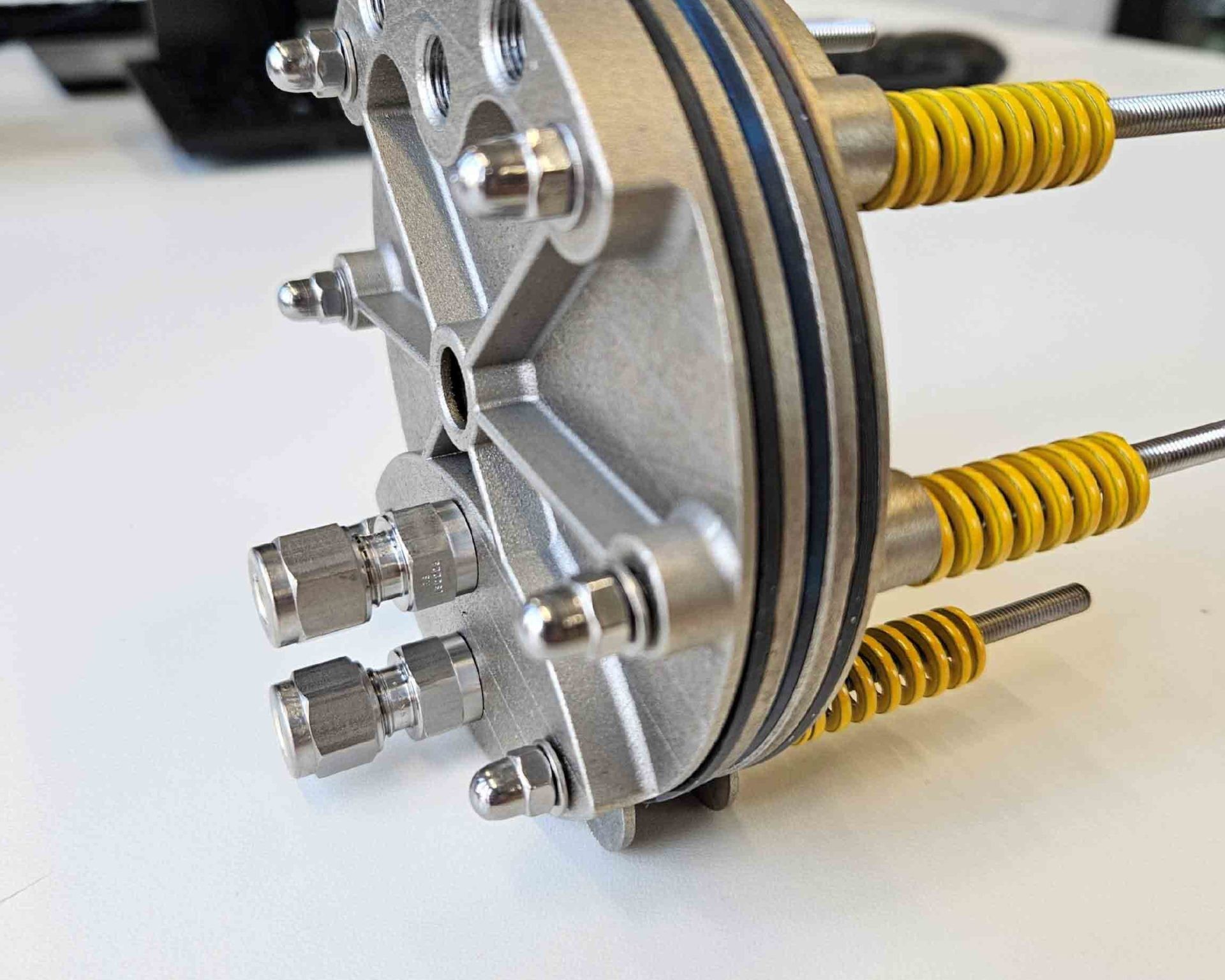

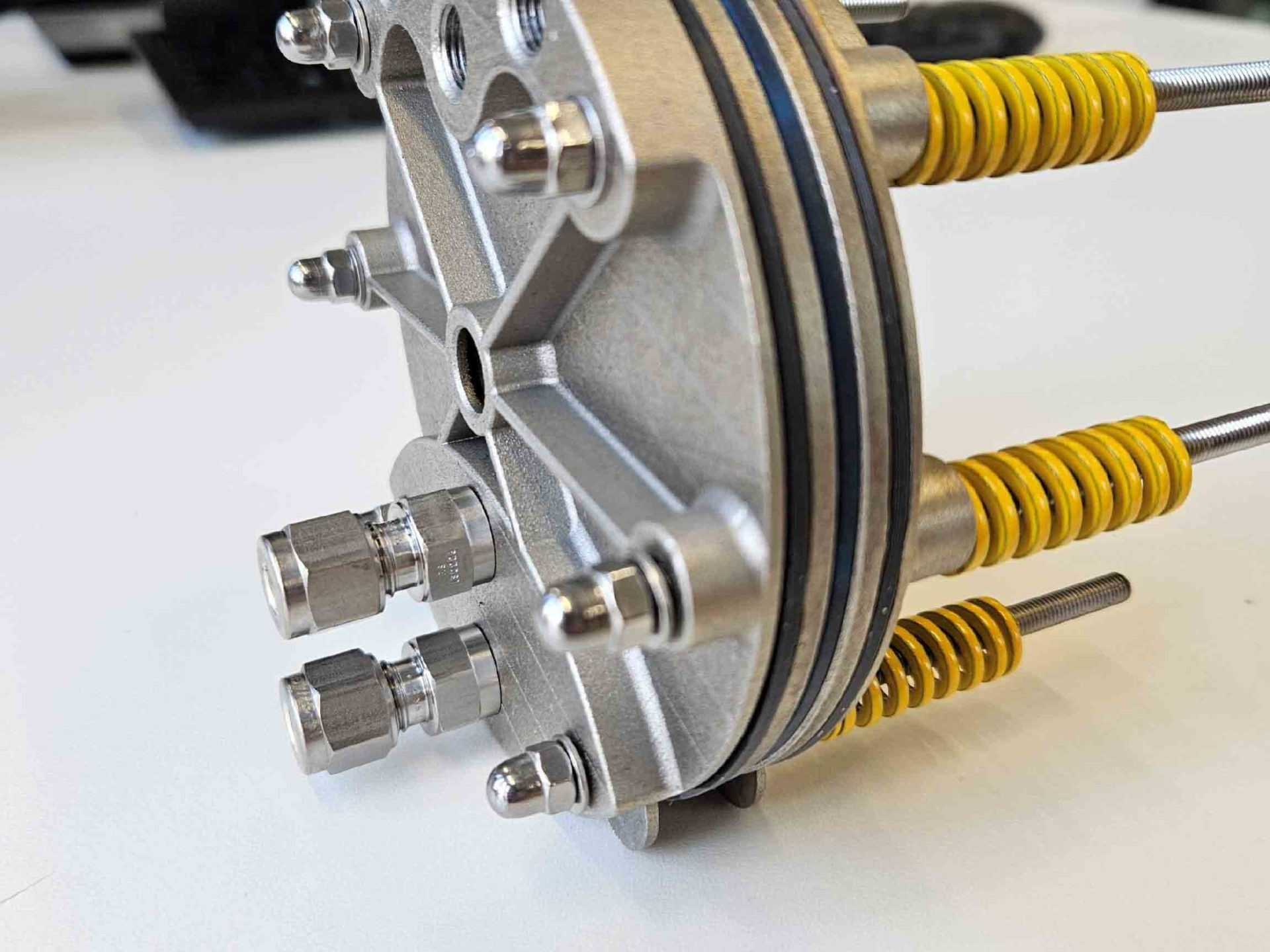

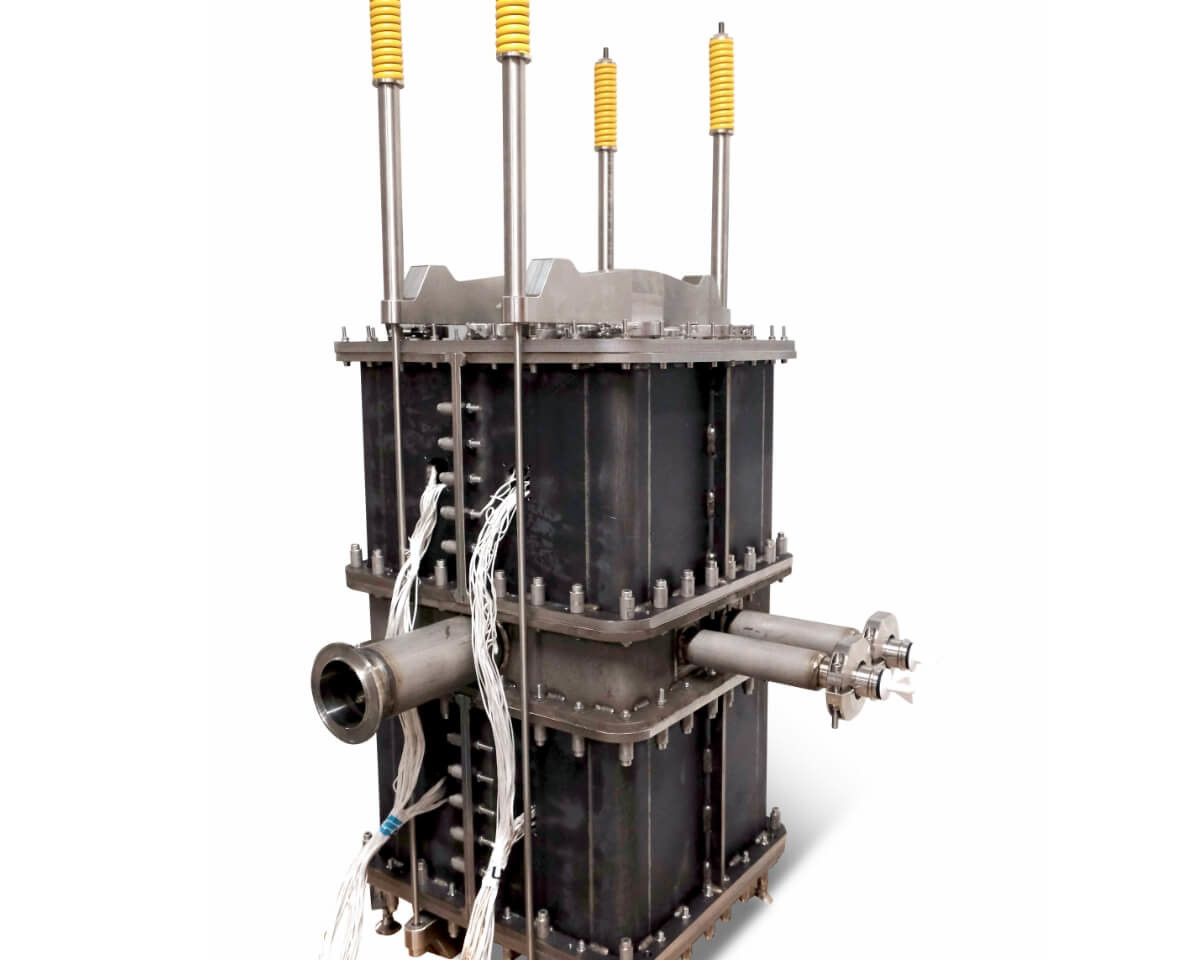

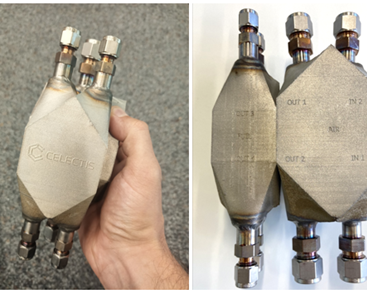

Celectis is providing subcomponents and test setups especially for fuel cell and electrolyzer systems such has high temperature heat exchangers, chemical reactors and green hydrogen production systems

- 300m2 of Fully Equipped LaboratoryCelectis boasts a 300 square meter fully equipped laboratory, providing state-of-the-art facilities for advanced research and development. Our lab enables comprehensive testing, prototyping, and validation of cutting-edge fuel cell technologies. Our laboratory is currently being upgraded with certified ventilation, gas lines, gas storage, etc. with financial support granted by the ScaleTec Energypolis program and the Canton of Valais trough a three-years funding enabling the construction of a Pre-industrial Fuel Cell Technology Innovation Platform in Valais.

- Innovative Technology and Assembly MethodsCelectis leverages innovative technology and advanced assembly methods to deliver high-efficiency energy solutions. Our approach includes mechanical design and simulations, additive manufacturing for components (especially metal 3D printing) and precision manufacturing techniques, ensuring superior performance and reliability in clean energy applications.

- Energypolis CampusIntegrated into the innovative Energypolis campus, Celectis benefits from close collaborations with leading academic and industrial partners. This integration provides access to cutting-edge research, state-of-the-art facilities and a dynamic ecosystem that accelerates progress in clean energy technologies.

- Strong Partnership with key Industrial PlayersCelectis has established strong partnerships with key fuel cell industry leaders worldwide. These collaborations enhance our expertise, drive innovation, and ensure the highest standards in fuel cell technology and applications. In addition, Celectis is also working within the process industry to provide novel solutions for reducing energy consumption.

Projects

Our clients never stop moving forward. Testing, challenging, pursuing the transformation that will transform everything. Every step of the way, we work alongside courageous leaders. Identifying the plan that will change tomorrow. Reaching net zero through using innovation. Using technology to change.

Need to know

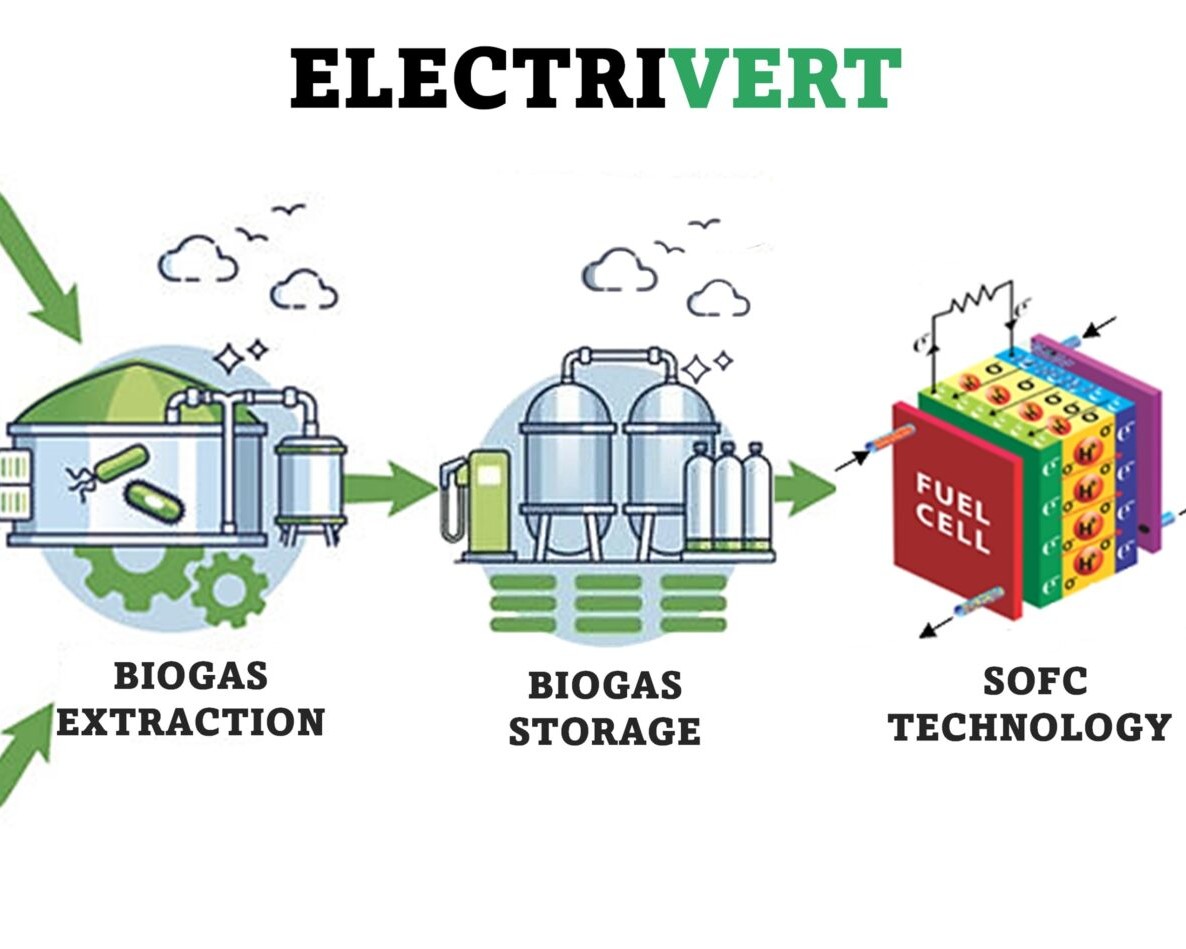

Solid Oxide Fuel Cells (SOFCs) represent cutting-edge technology in the field of clean energy. Understanding the intricate details of their operation and materials can significantly enhance their application and performance.

SOFCs achieve high efficiency in cogeneration by operating at high temperatures, allowing for internal reforming of light hydrocarbons and efficient heat utilization.

Common materials for the ceramic electrolyte in SOFCs include yttria-stabilized zirconia (YSZ) and scandia-stabilized zirconia (ScSZ).

SOFCs operate at high temperatures which allow them to tolerate sulfur and avoid carbon monoxide poisoning by preventing catalyst deactivation.

Current research focuses on enhancing SOFC performance and durability through advanced materials, improved sealing technologies, and optimized system integration.

innovation ⸺ sustainability ⸺ expertise ⸺ proximity ⸺ unique ⸺

Our partners

Celectis was born on the new Energypolis campus based in Sion (Valais – Switzerland). The company is therefore strongly integrated into this innovative ecosystem.

These strong collaborations with local academic and industrial partners provide Celectis with exceptional know-how on today’s major issues in the fields of energy and the environment, thanks to cutting-edge technologies.